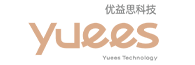

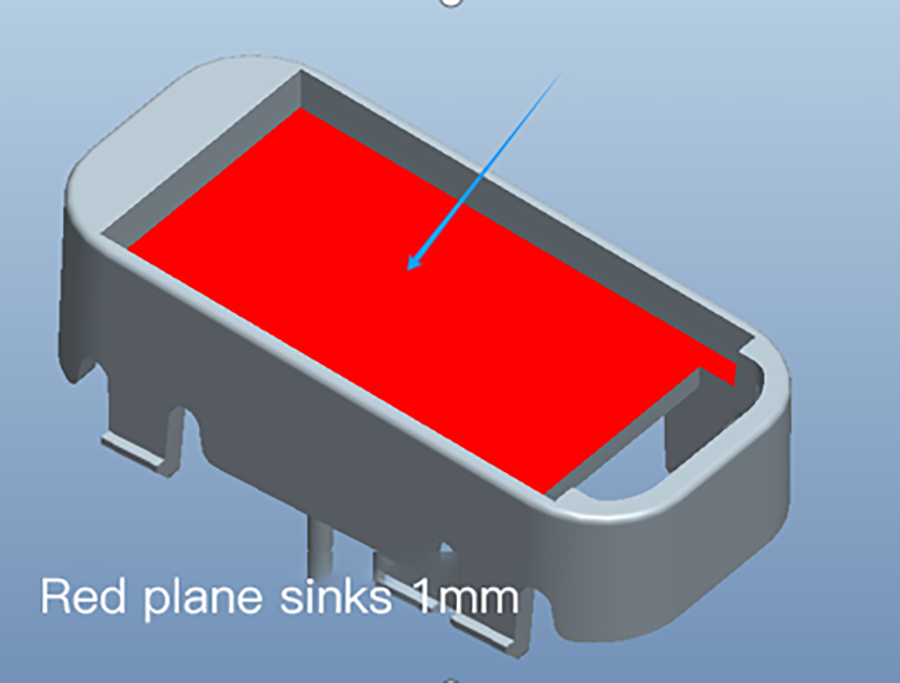

During the production process of the 3401 abdominal wheel, due to the small clearance between the display screen and the display cover, employees need to be careful during assembly to prevent the display screen from being crushed by the display cover, which leads to reduced efficiency and the proportion of defective products is not more than 4%. | 1: Reduce the glue on the red side of the display bracket by 1 mm to let the screen sink away from the contact force surface, 2: Add glue to the blue side of the black semi-transparent part to make the whole plane, and use the display bracket as a force support for the semi-transparent part to avoid contact with the screen |

When the product was designed, there was insufficient clearance between the structure of the upper cover and the display screen, which resulted in the upper cover easily coming into contact with the display screen when it was buckled, causing the display screen to be subjected to external force and resulting in damage. | After the mold was improved, a total of 7,000 PCS of this model were put into production from March to April 2025, and no screen explosion occurred. The efficiency of this process on the production line was increased from 75 units per hour to 105 units per hour, effectively improving the quality of the one-time installation pass rate and the output of the production line. |